What is the control panel of commercial embroidery machine

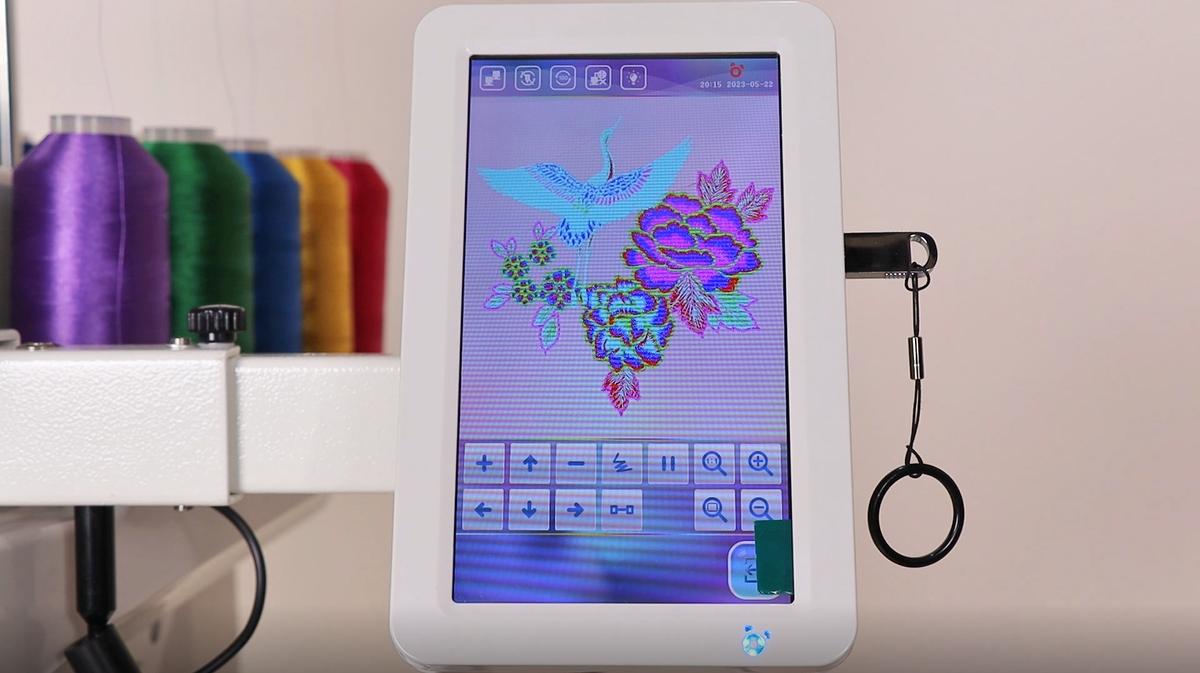

1. Touch Screen Display: Both of our modern commercial embroidery machines are equipped with a color touch screen display that provides an intuitive interface for the user to interact with the machine. The touch screen allows users to navigate menus, enter design parameters and make adjustments with ease.

2. Pattern input: Customers can input and select embroidery patterns through the control panel during operation. This may involve loading designs from a connected computer or USB drive, accessing designs stored in the machine's memory, and adjusting design placement and orientation on the fabric.

3. Stitch parameters: Customers can adjust various stitch parameters, such as stitch density, stitch length, underlay setting and thread tension. These settings affect how the embroidery design is sewn onto the fabric.

4. Thread color selection: Customers can usually use the color palette displayed on the control panel to choose the thread color for each part of the design.

5. Design editing: Basic design editing functions can be used through the control panel. Customers can resize, rotate, mirror or flip designs directly on the machine.

6. Thread trimming: Commercial embroidery machines often have an automatic thread trimming function. Customers can control when and how the machine trims the thread between color changes or at the end of each segment.

7. Machine speed: The control panel allows customers to adjust the speed of the embroidery machine. This is important for optimizing production and achieving the required level of detail and accuracy.

8. Tension adjustment: Thread tension plays a vital role in achieving high-quality embroidery. The control panel allows users to adjust thread tension for different types of embroidery projects and fabrics.

9. Start, stop and pause: the control panel provides buttons for starting, stopping and pausing the embroidery machine. This gives the customer control over the stitching process and allows them to troubleshoot any issues that may arise during the embroidery process.