How is the cap embroidery of commercial embroidery machine completed

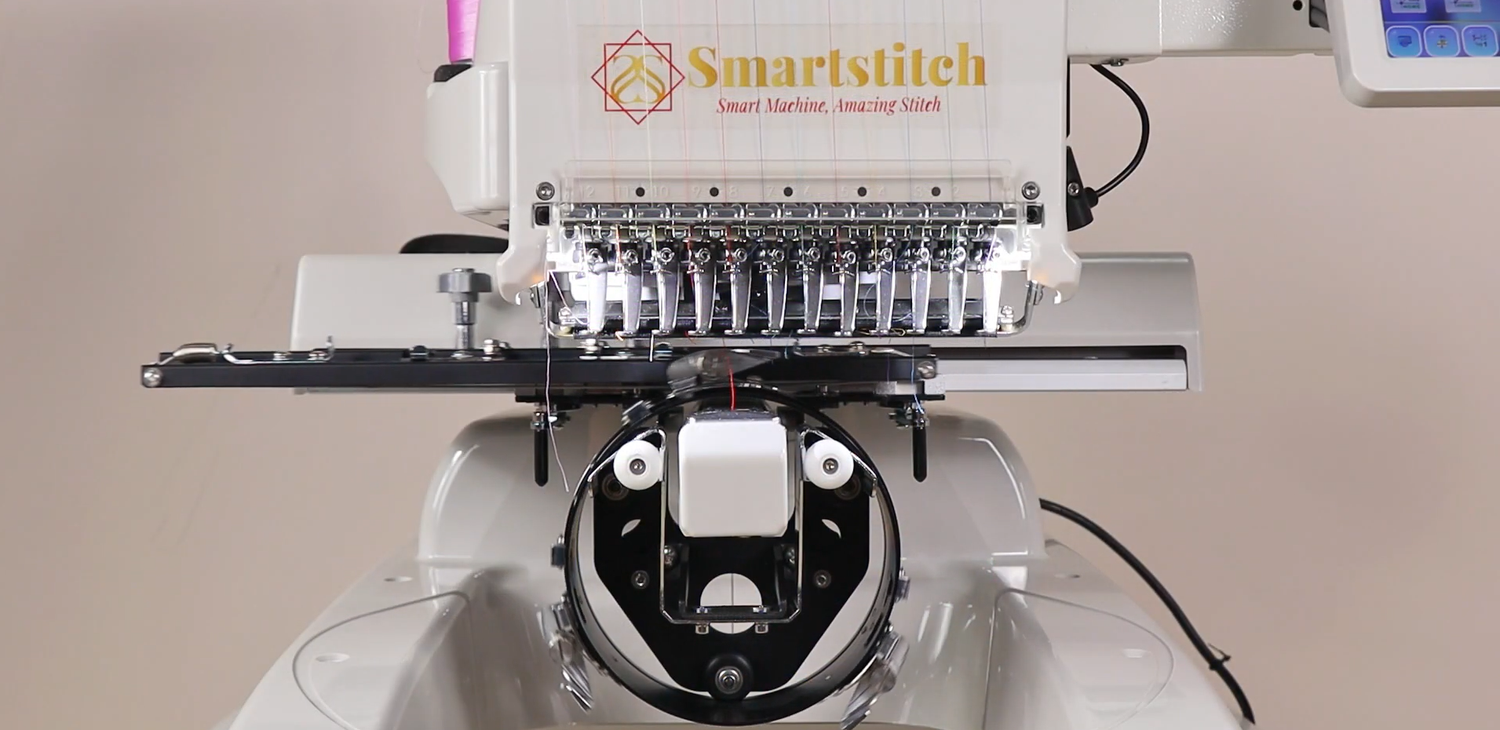

1. Machine setting: S1201 is equipped with 12 needles, and S1501 is equipped with 15 needles, which can thread threads of different colors at the same time. For hat embroidery, we have a special hat frame or hat hoop. The frame holds the hat in place and ensures accurate positioning during embroidery.

2. Design Digitization: The first step is to create or obtain a digital embroidery design. Design files can be created using embroidery digitizing software, which converts artwork or logos into stitch patterns. The supporting software we use is software, and we will explain in detail how to use this software well in the following oral broadcast video.

3. Hoop preparation: Attach the hat frame to the embroidery machine and place the hat in it. The front panel of the hat should face up and the frame ensures the hat stays taut and centered for precise embroidery

4. Thread selection: According to the design, select the appropriate thread color and thread it into the corresponding needle position on the machine. Each needle can hold a different color of thread.

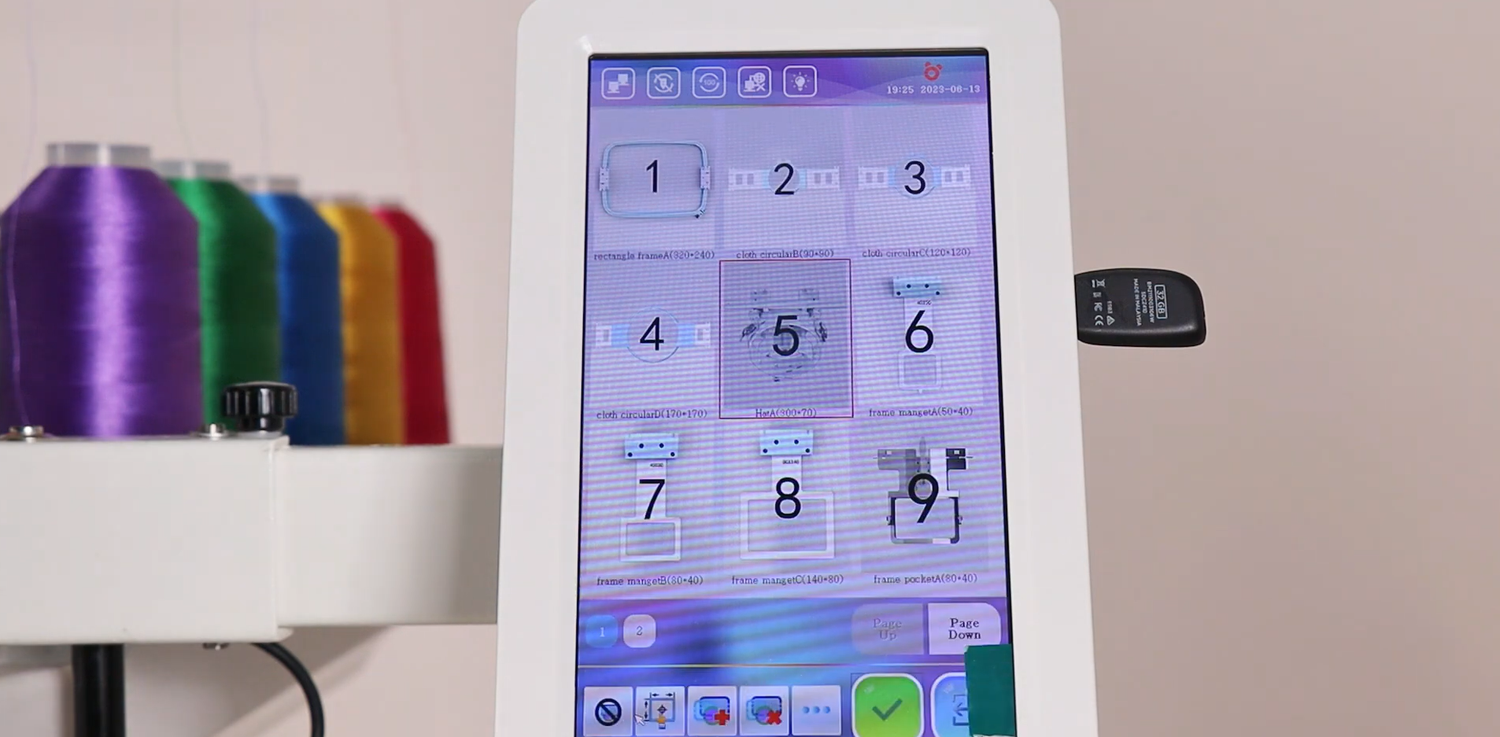

5. Machine programming: Load the design file into the control panel of the embroidery machine. USB used by our commercial embroidery machines. After importing, set parameters such as thread tension, sewing speed and any necessary design adjustments.

6. Embroidery process: After everything is set, the machine starts the embroidery process. It moves the cap frame and needle according to design instructions, creating stitches and patterns with selected thread colors. The cap frame can be moved in all directions, allowing the needle to create intricate designs.